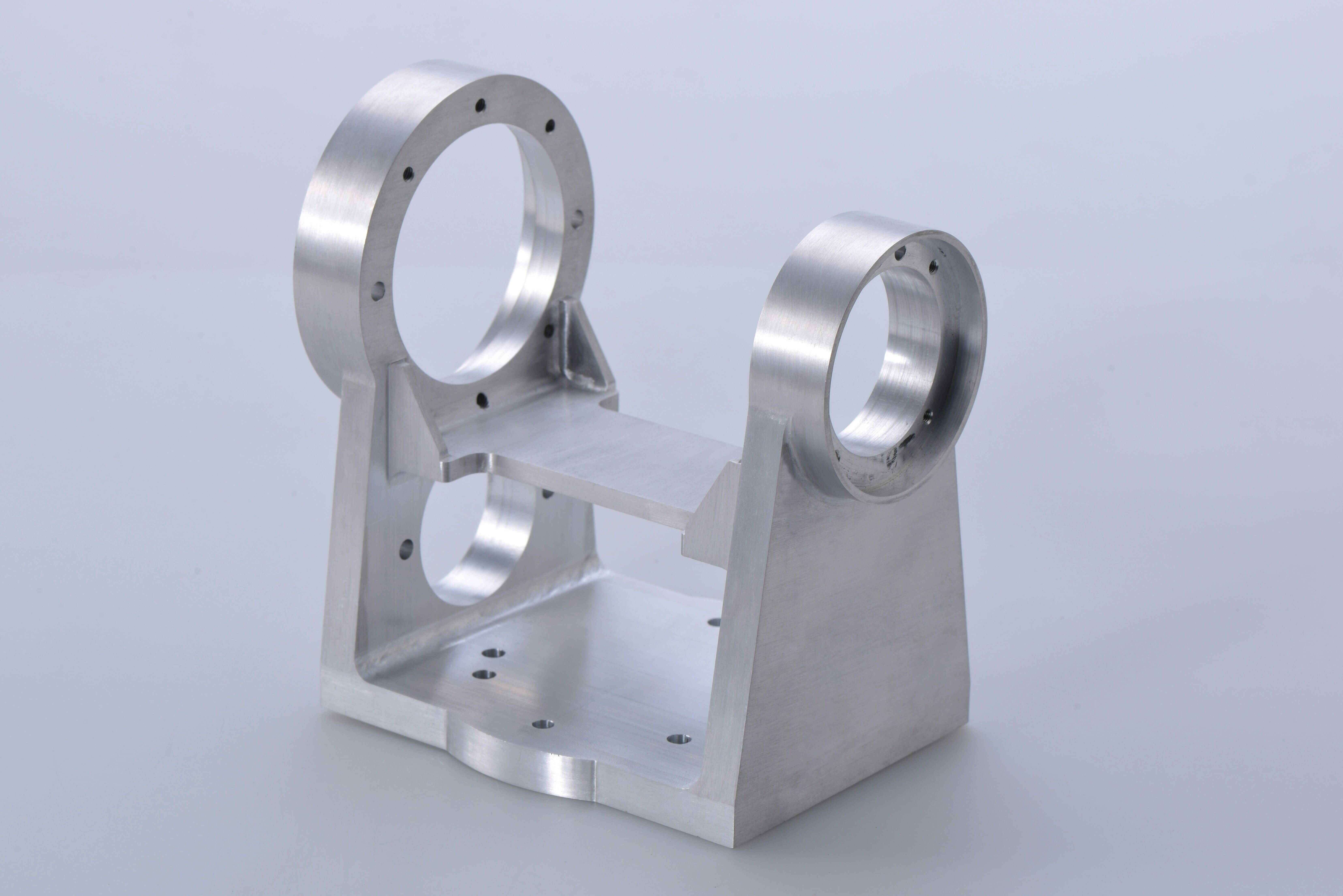

Design and Development

CNC Machining

We have an advanced CNC manufacturing unit in hyderabad that can shape both heavy duty and tiny parts according to customer requirements.

PROFFESSIONALISED PARTS MACHINING.

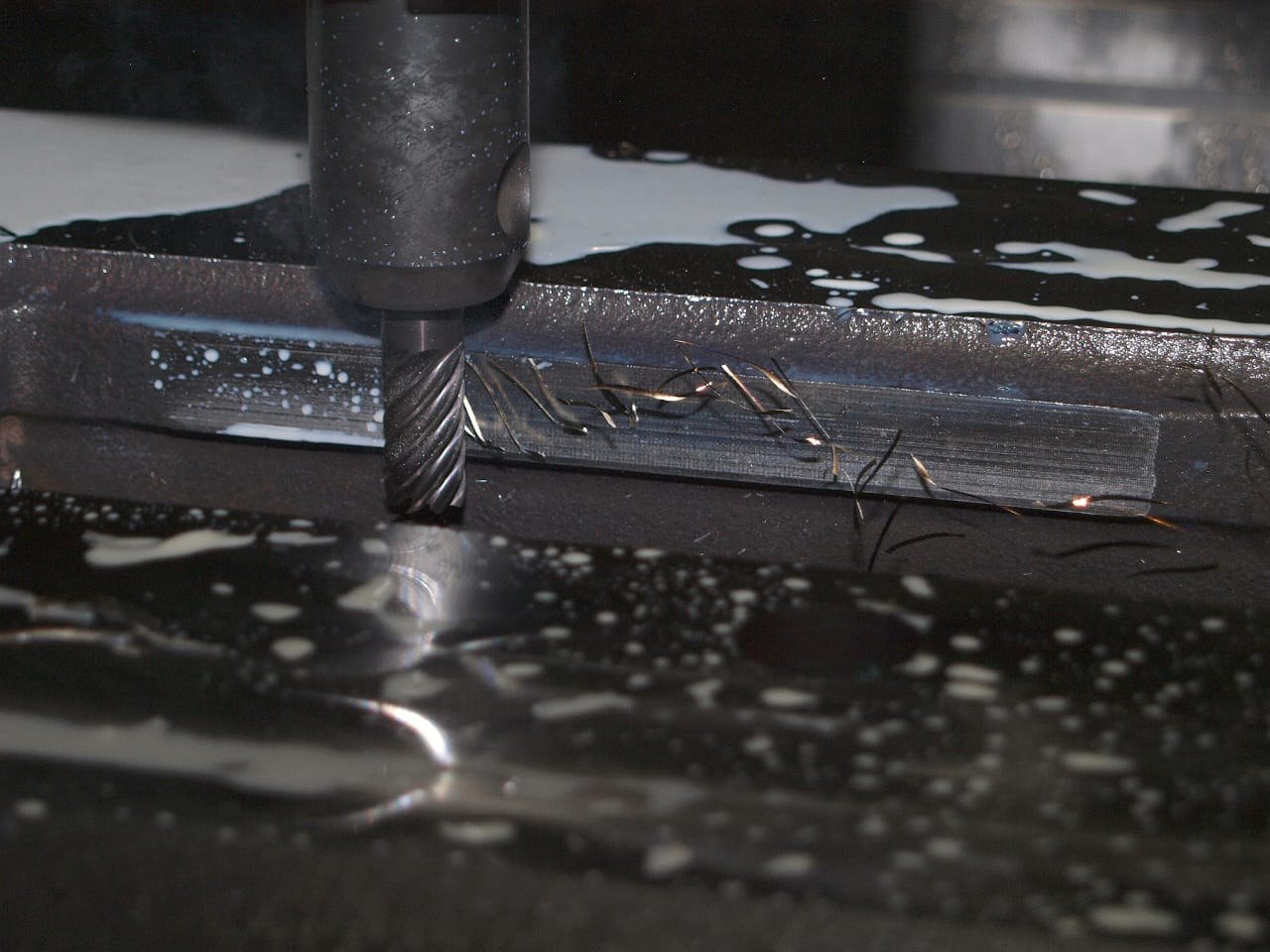

CNC Milling

CNC milling is a metal-cutting method that uses automated machine control to produce very precisely shaped parts at a high rate of production. We provide 3 and 5 axis machining. Highly trained and qualified proffesionals will assist our customers to provide good quality product.

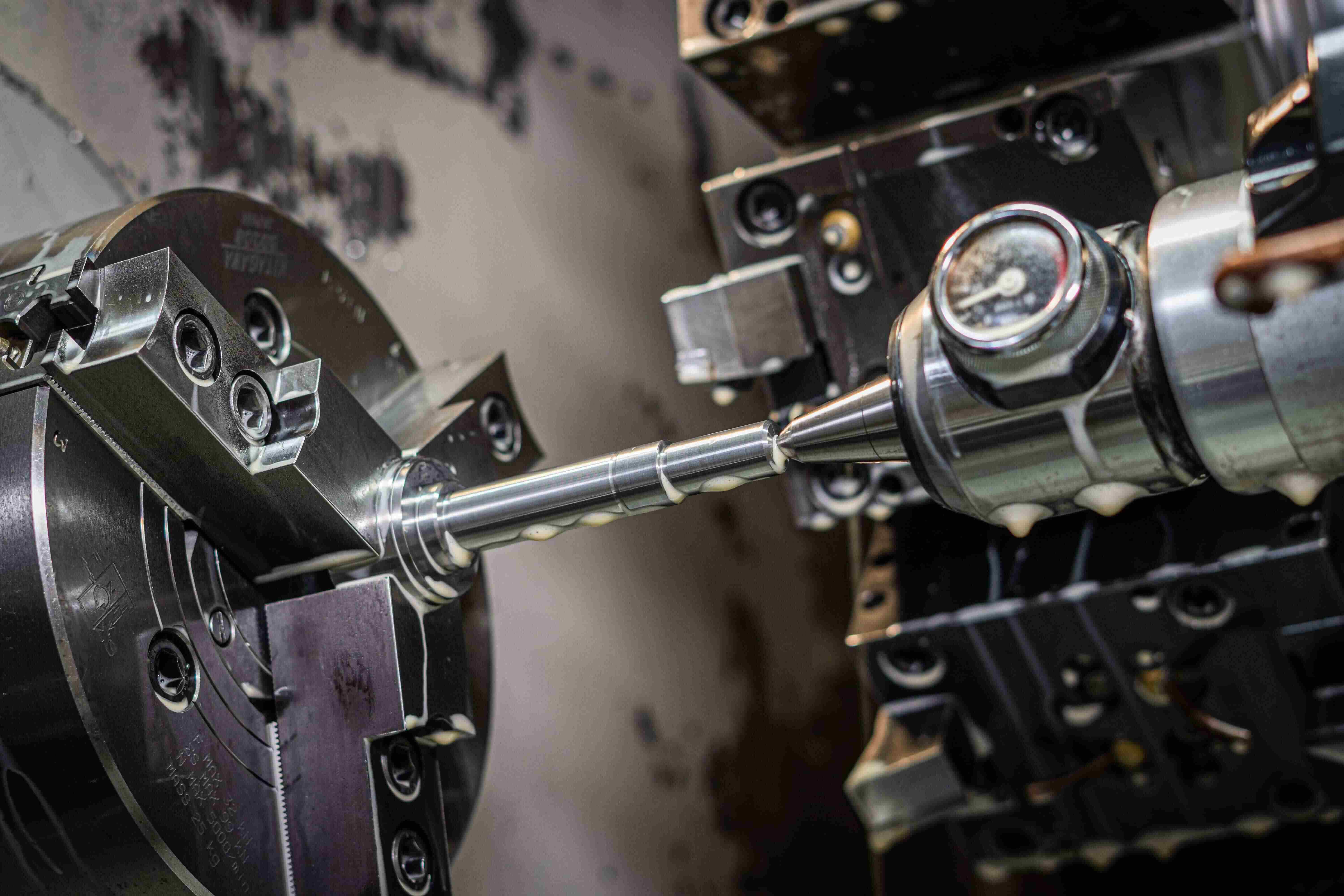

CNC Turning

CNC turning service is suitable for creating cylindrical parts. Highly skilled machinists can create precision parts on all types of CNC lathes. We at Design and development, takes care of everything from quoting to delivery

CNC Materials

Metals

Aluminum: A most widely used metal because of its high strength. Its a low cost and recyclable material good for every use either large products or small products.

Brass: Brass is a easily machinable metal which is used in many applications including gears and pipe fittings. It can handle high temperature and it has high resistance to corrosion.

Copper: Copper is a versatile metal that is suitable for a wide array of applications such as pipes, electric cabling, circuit boards, electronics, wiring, radiators and cooling systems

Stainless Steel: The popularity of stainless steels as a machining material mostly comes from their unique balance of properties. Stainless steels are relatively hard, with a high mechanical strength that can be increased even further using heat treatments.

Plastics:

Acrylic: It is also reffered as PMMA. Many industries make use of acrylic as a replacement for glass since it is shatterproof. It is a colorless and clear polymer that can come in different forms.

Polycarbonate: Polycarbonate materials offer good machinability with excellent dimentional stability. It has high impact strength and stiffness.

Nylon: Nylon is a popular material for CNC machining due to its ease of machining, low cost, and robustness. It is used as a substitute for low-strength metals like steel, copper, and iron in the CNC machining process.

ABS: ABS is a resin with favorable comprehensive characteristics and excellent dimensional stability. ABS exhibits impressive mechanical properties, such as excellent impact strength, enabling it to be employed at very low temperatures.

Product Surface Finshes

As-Machined

As-machined parts are fresh off the line with minor tool marks and average surface roughness, and many are molded to already have a specific texture or finished look. The benefits of an as-machined finish include consistency between multiple units and the tightest dimensional tolerances.

Anodized finish

anodizing is a passivation process that creates a protective layer on aluminum parts. Due to the coating's porous nature, anodized parts can also be dyed, painted, and sealed.

Bead Blasting

Bead blasted parts have a matte finish with a light texture. It’s mainly used to improve a part's visual appearance. An advantage of bead blasting is its uniform and textured finish.

Powder coating

Powder coating is used on steel, stainless steel, and aluminum, and is similar to painting your part. Powder coating comes in a variety of colors and gloss levels and creates a thick, smooth uniform coating to provide increased durability.